The connection of the EBS storage ring to its vital services is in full swing, with over half of the ring already connected to the water-cooling system and a full cell of components cabled to the Control Room.

Water cooling pipes are in place around half of the ring. Credit: C. Argoud/ESRF.

Water cooling pipes are in place around half of the ring. Credit: C. Argoud/ESRF.

The piping and cabling phase follows the successful installation of 129 girders in May 2019. Since then, teams of 20 plumbers and 80 electricians have been working at speed to complete the installation of the ancillaries.

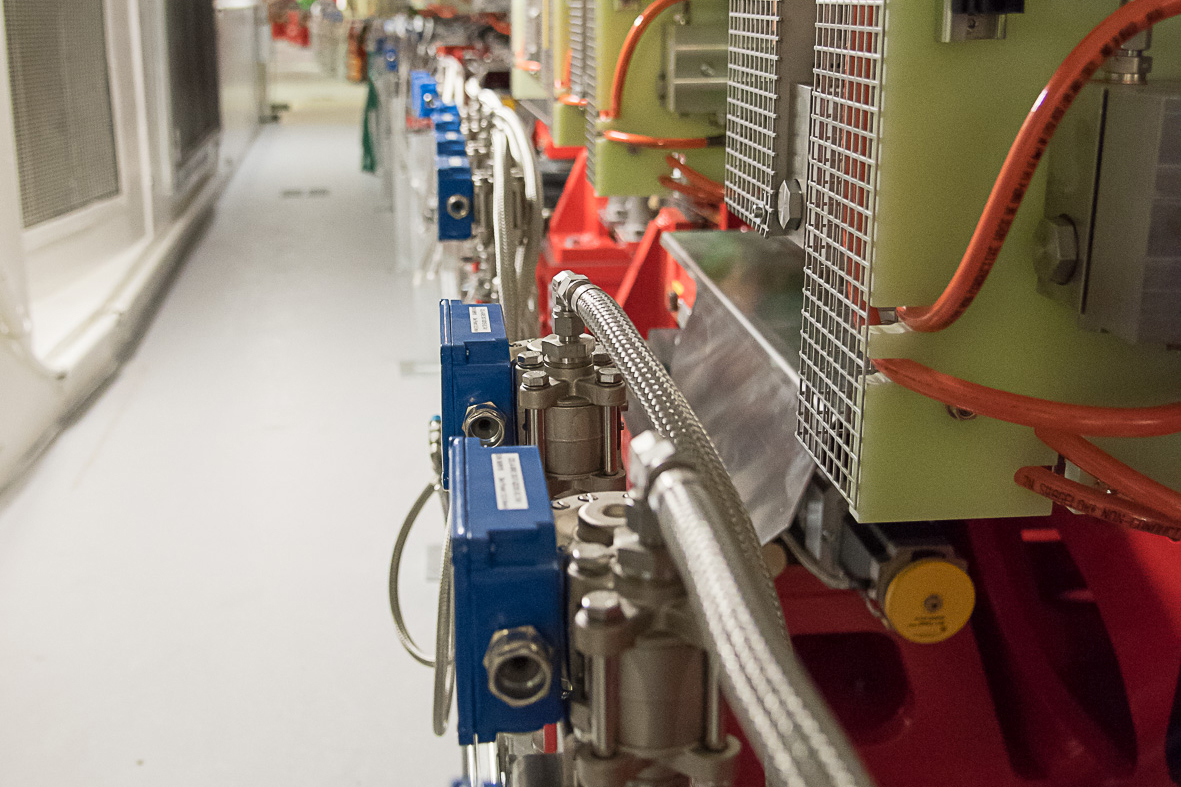

1200 flow meters (in blue) control the water cooling network for the EBS equipment. Credit: C. Argoud/ESRF.

1200 flow meters (in blue) control the water cooling network for the EBS equipment. Credit: C. Argoud/ESRF.

Like much of the EBS, the scale of the task is impressive.

For the piping alone, the shopping list contains 3300 flexible pipes, 4500 valves and 1200 flow controllers.

Once complete, around 5.5 km of pipes will carry over 10,000 litres of water around the ring to ensure that equipment including 900 electromagnets does not overheat while in operation.

Over 5 km of pipes encircle the EBS storage ring. Credit: C. Argoud/ESRF.

Over 5 km of pipes encircle the EBS storage ring. Credit: C. Argoud/ESRF.

Piping an entire cell (there are 32) takes four weeks, followed by four weeks of cabling, but several cells are worked on in parallel.

“Around half of the storage ring is now piped and connected,” confirmed Frédéric Favier, head of the Fluids Unit in the Buildings and Infrastructure group.

13,000 electrical, network and signal cables connect cutting-edge equipment to the Control Room. Credit: S. Candé/ESRF.

13,000 electrical, network and signal cables connect cutting-edge equipment to the Control Room. Credit: S. Candé/ESRF.

Although this marks another step on the road to completing the EBS, there’s no time to celebrate.

Once the piping is finished, the installation of 13,000 cables connecting equipment to the Control Room must be completed before the beginning of October. First tests without beam will be carried out immediately after, followed by the start of machine commissioning with beam in November.