With the installation phase of the ESRF’s Extremely Brilliant Source (EBS) well underway, eyes are often drawn to the 128 girders full of cutting-edge equipment being manoeuvred into its storage ring tunnel. On the other side of the tunnel wall, however, is another realm of activity just as important to the success of the world’s first high-energy, fourth-generation synchrotron.

Here lies the Technical Zone.

The Technical Zone plays a huge role in the success of EBS. Credit: Stef Candé/ESRF.

The Technical Zone plays a huge role in the success of EBS. Credit: Stef Candé/ESRF.

If the storage ring, with its innovative new lattice configuration, is the beating heart of the EBS, then the Technical Zone is the circulatory system of arterial cables and pipes that connects magnets, detectors and myriad other equipment from the storage ring via controllers to the brains of the operation – the Control Room.

Metres of cables and pipes link the hardware in the storage ring to the software in the Control Room. Credit: C. Argoud/ESRF.

Metres of cables and pipes link the hardware in the storage ring to the software in the Control Room. Credit: C. Argoud/ESRF.

“The Technical Zone is the link between the machine and the Control Room but also between all the different groups of expertise,” explains Benoit Joly, coordinator in the Technical Zone. “It’s a place where everyone works together, interdependently.”

Power supply engineer Jean-Marc Gay works on an electrical cabinet. Credit: C. Argoud/ESRF.

Power supply engineer Jean-Marc Gay works on an electrical cabinet. Credit: C. Argoud/ESRF.

Indeed, electricians, software and network specialists and experts in vacuum, alignment, RF, power supplies, diagnostics and other parts of the accelerator all rub shoulders here during the installation phase, preparing or refurbishing equipment and optimising the layout of more than 500 electrical cubicles that control the EBS’s individual components.

Power supplies technician Pierrick Sallamand (left) and operator Razihan Karakas (right) cable electrical racks in the Technical Zone. Credit: C. Argoud/ESRF.

Power supplies technician Pierrick Sallamand (left) and operator Razihan Karakas (right) cable electrical racks in the Technical Zone. Credit: C. Argoud/ESRF.

Cabling is one of the most significant tasks for the groups – over 13,000 cables must be individually pulled and connected by hand! These include electrical cables that power the electromagnets, signal cables that carry signals to computers and network cables to link computers both to each other and to the Control Room.

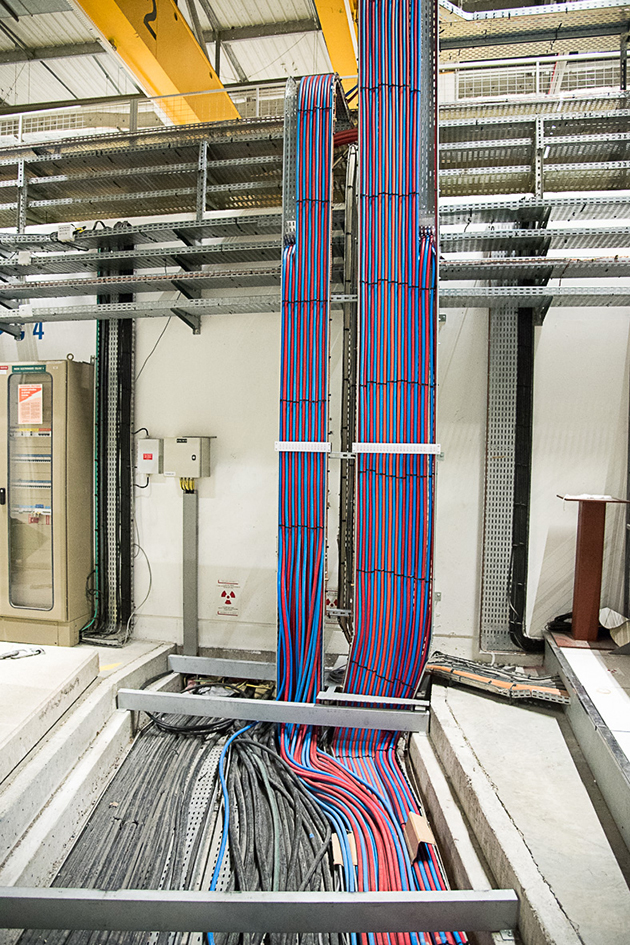

A waterfall of cables in the Technical Zone! Credit: Stef Candé/ESRF.

A waterfall of cables in the Technical Zone! Credit: Stef Candé/ESRF.

Another big project is the preparation of 32 new intelligent ‘hot-swap’ electrical cubicles for the storage ring that automatically switch the electromagnets from one power supply to another in the case of a power supply failure, vastly improving the reliability of the machine.

Power supply engineer Stephane Lagarde installs a new 'hot-swap' electrical cabinet. Credit: JL Revol/ESRF.

Power supply engineer Stephane Lagarde installs a new 'hot-swap' electrical cabinet. Credit: JL Revol/ESRF.

Once installation is complete, every single connection on each piece of equipment will need to be tested. During this part of the commissioning phase, operation manager Jean-Luc Revol estimates that over 50,000 separate connections will have to be made and tested!

Over 20,000 connections will be made for the EBS magnets alone. Credit: Stef Candé/ESRF.

Over 20,000 connections will be made for the EBS magnets alone. Credit: Stef Candé/ESRF.

Revol and the teams are ready for the challenge, though.

“Thanks to everyone’s hard work, the machine is coming back to life,” he says.

Here, in the Technical Zone, where teams and equipment swap information in an endlessly connected hub, it is clear that many hands make the EBS work.